Canton Innovation and Community Center Ribbon Cutting

Last night, William V. Sherer II, Mayor of Canton and Jeff Dafler, President & CEO of the Canton...

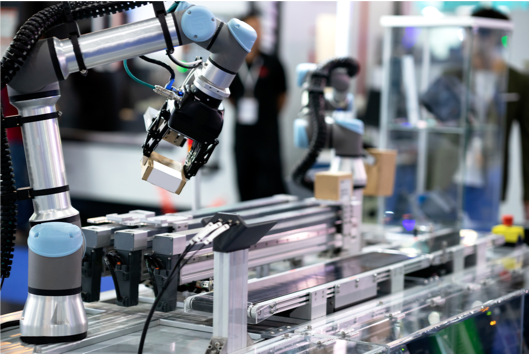

Manufacturing

growth partners.

We’re manufacturers who work closely with your team to create measurable results. High-touch, high-impact consulting is part of our DNA.

We roll up our sleeves

Our diverse team of manufacturing experts use their skills and expertise to make good things great, to make great things excellent, and aim to make excellence standard in Ohio.

Building Northeast Ohio’s Future

Connecting with and changing the lives of Northeast Ohioans through smart manufacturing

Last night, William V. Sherer II, Mayor of Canton and Jeff Dafler, President & CEO of the Canton...

Again this year, MAGNET has been selected as a 2024 Smart Culture Award Honoree by Smart Business....

The National Association of Workforce Development Professionals (NAWDP) announced MAGNET has been...

Last week, MAGNET's ACCESS to Manufacturing Careers program graduated 20 candidates who are now...

MAGNET: The Manufacturing Advocacy and Growth Network reported on the progress made in advancing...

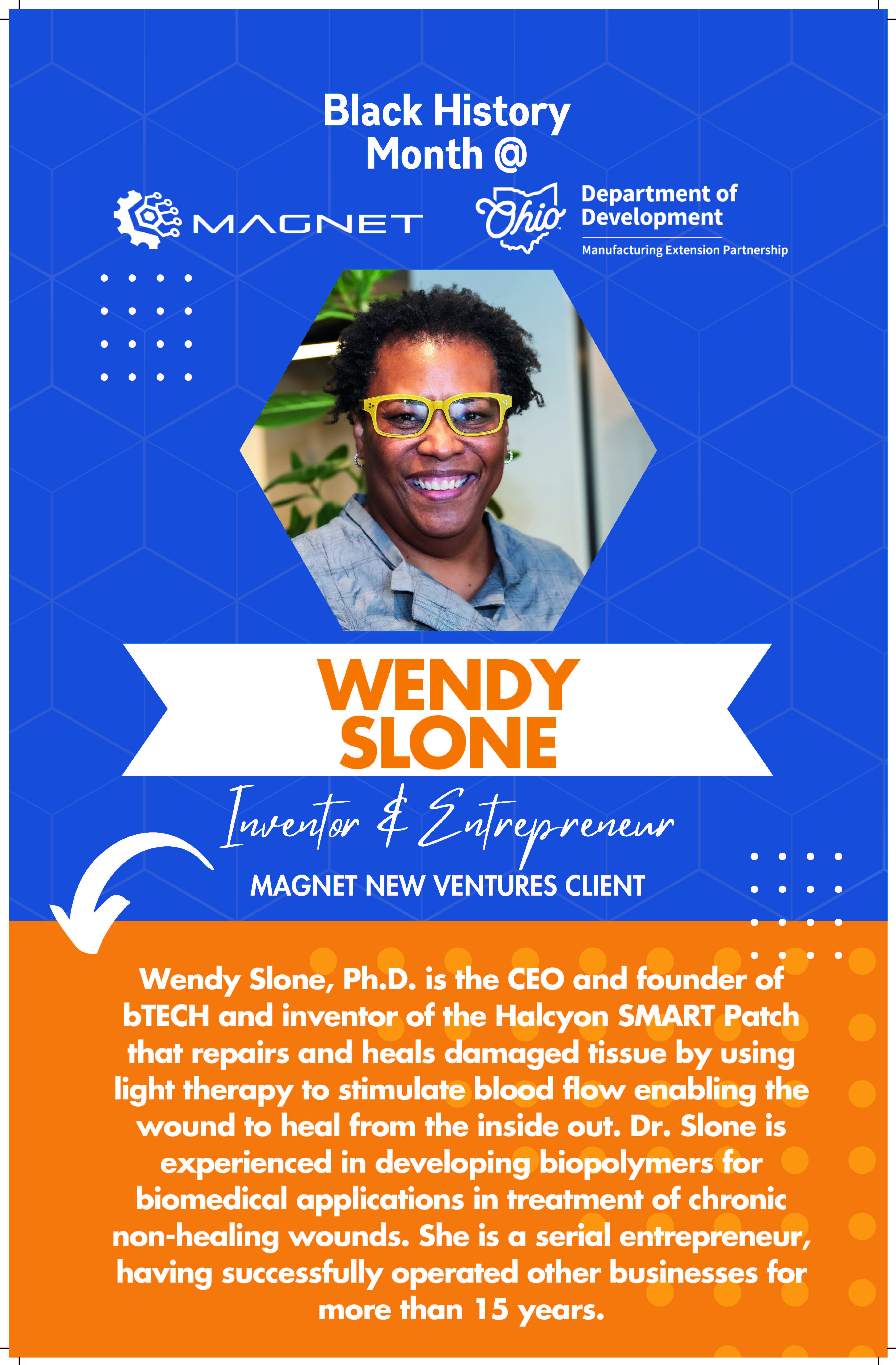

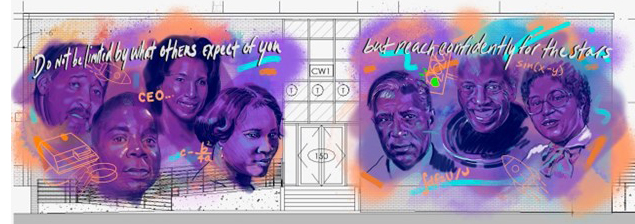

We are fortunate to have strong black role models in manufacturing, engineering and...

The first Lighthouse Tour of 2024 took place at Great Lakes Growers, who opened the doors of their...

MAGNET’s 8th annual Mspire pitch competition brought together the best and brightest in the...

Many Clevelanders don’t realize what a space gem we have right in our own backyard! NASA’s Glenn...

Mid’s Homestyle Pasta Sauce is a tradition 65 years in the making, when Mideo Octavio first bottled...

EDGE’s Innovation Management Program, InnoQuest, brings together innovation leaders from 20+...

Rimeco Products, Inc. President John Ribic, Jr. welcomed guests for MAGNET’s October Lighthouse...

Last week was the first official bike ride for Mary B. Martin’s 8th grade engineering students to...

MAGNET’s Strategy, Marketing & Sales (SMS) team has been busy helping clients from all corners of...

Founded in 1971, Troy Chemical Industries specializes in the manufacturing, packaging and shipping...

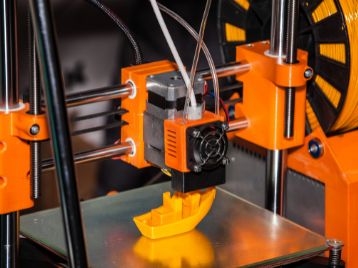

As technology continues to evolve at a rapid pace, 3D printing has emerged as a game-changing...

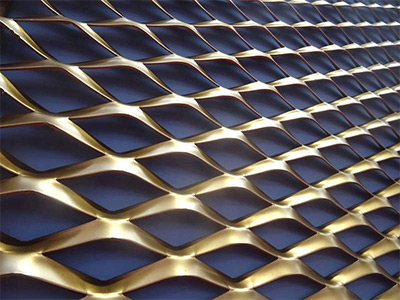

Niles Expanded Metals & Plastics, located in Niles Ohio, manufactures and distributes expanded...

Manufacturing offers career endless opportunities to individuals with any skillset or level....

When MAGNET outgrew its headquarters, we could have found nondescript industrial space in the...

Cleveland-based full-service IBC tote management provider Premier Container has more than 30 years...

I walked through our workshop the other day and some of our engineers were hanging upside down off...

Great Lakes Growers is a premier grower of clean lettuces and herbs. Their Burton, Ohio-based...

All of today’s manufacturing careers require creativity, problem-solving, leadership, diligence,...

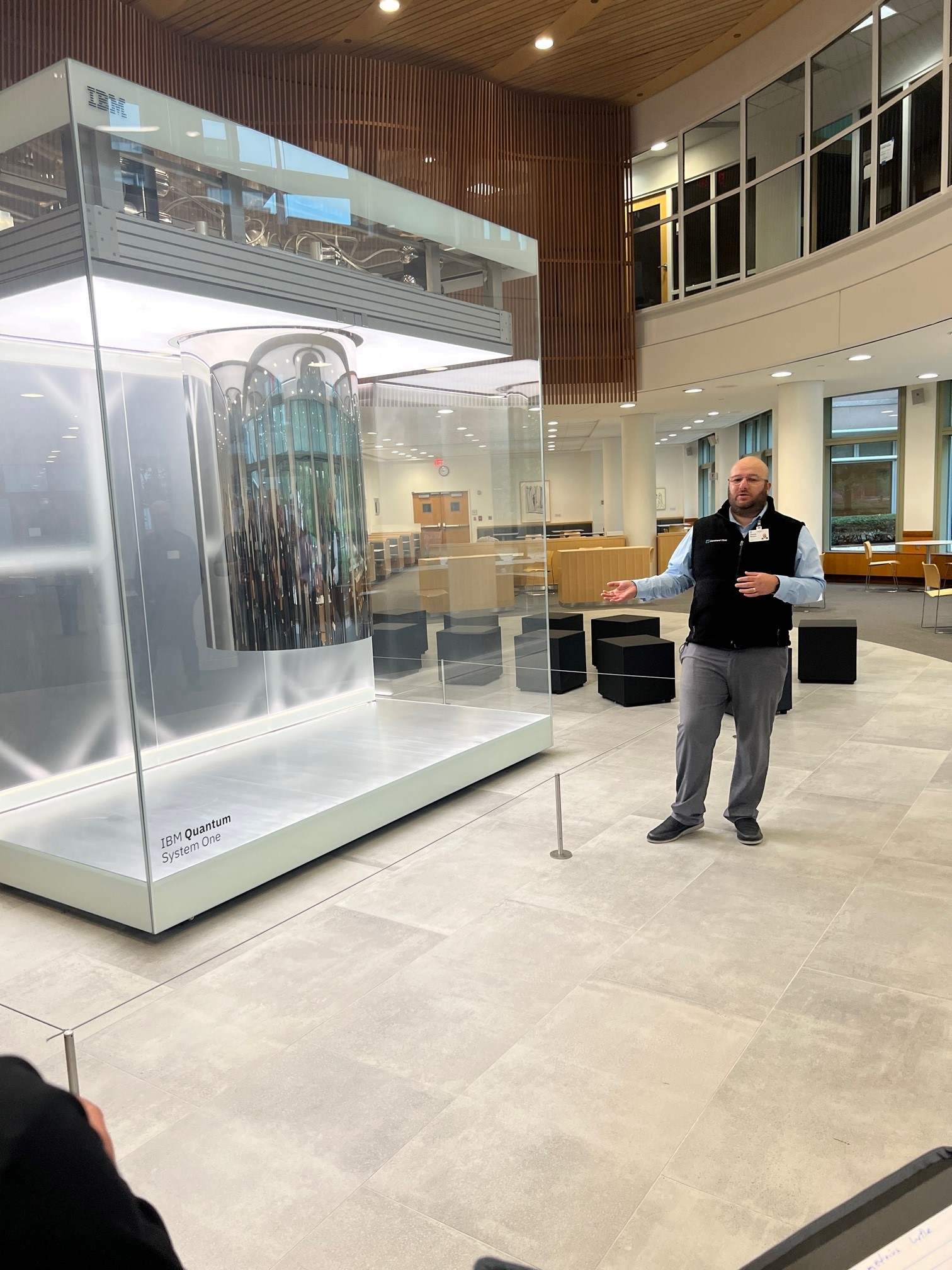

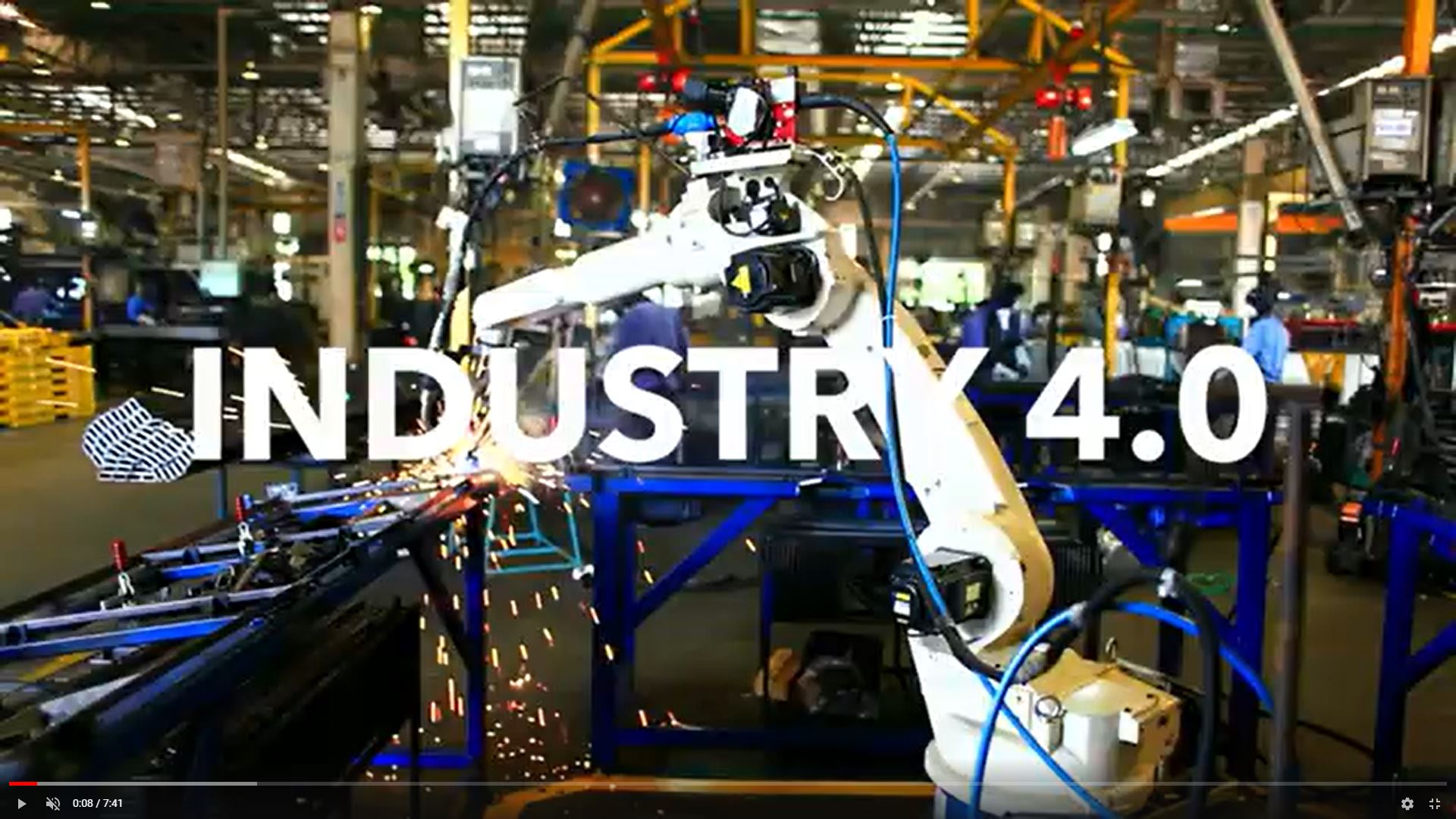

Helping Northeast Ohio manufacturers go from lagging to leading in Industry 4.0 is a critical focus...

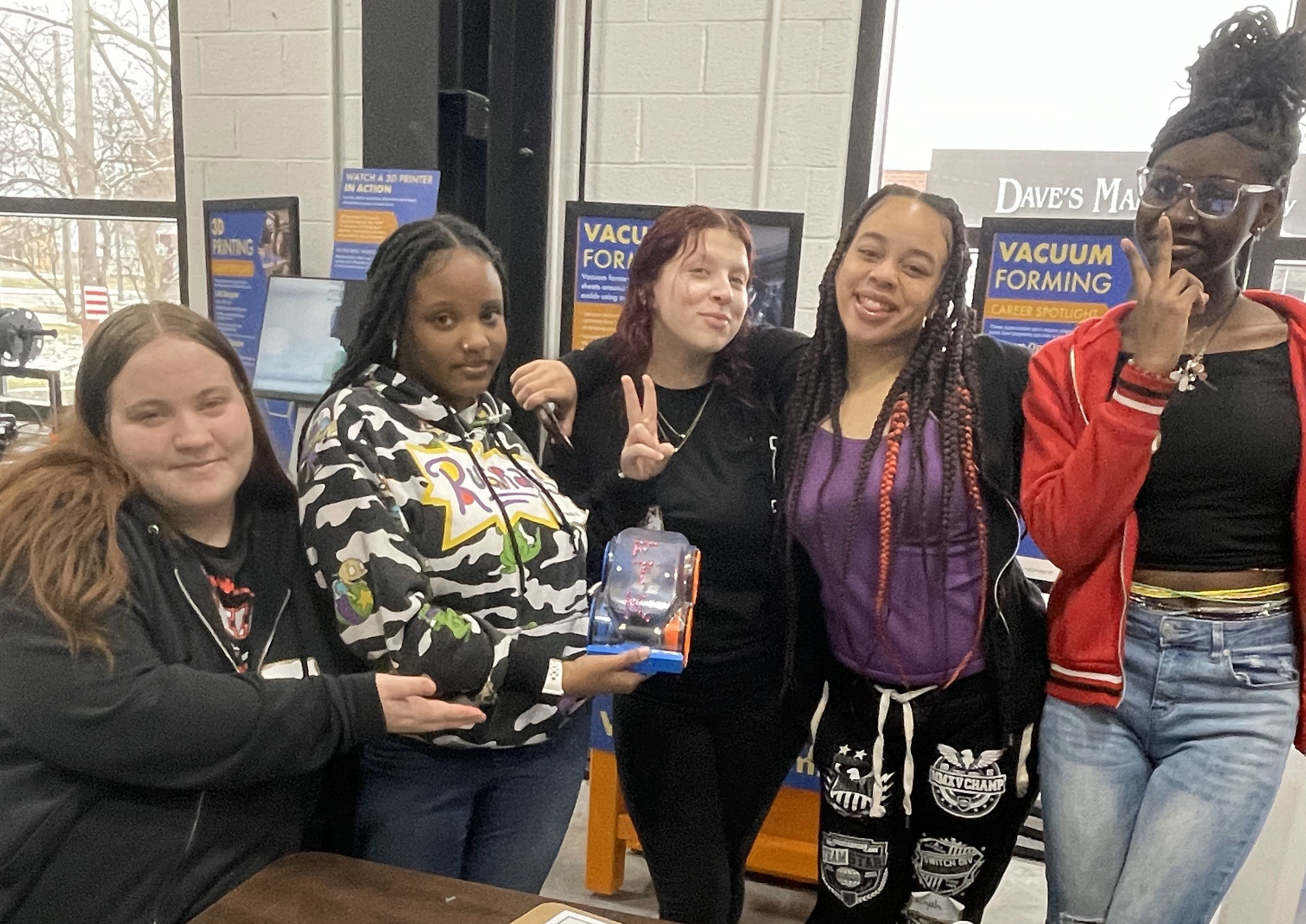

It’s graduation season and MAGNET is no exception. We recently graduated our largest class from the...

Efficiency through Transformation to Industry 4.0. Growth through Innovation. Prosperity through...

Interested in how manufacturing impacts Northeast Ohio? Want to learn about the lucrative careers...

Music pumping. Giant inflatables. STEM-themed activities. Fresh energy surrounded the shuttered...

Parkman, Ohio manufacturer Montville Plastics and Rubber has been a custom plastic extruder and...

Mario Gross graduated from ACCESS to Manufacturing Careers in March of 2022. Since then, not only...

The vision set forward by The Blueprint for Manufacturing in Northeast Ohio inspires all of...

OmegaOne, a manufacturer of stainless-steel hose fittings in Willoughby, Ohio, was looking to grow...

Manufacturers, foundations and individuals donated $13 million to gut and renovate the former...

Innovation Food Services (IFS), originally founded in 2002 as Red’s Catering, started as a food...

Two years ago, the Cleveland Metropolitan School District (CMSD) voted unanimously to allow MAGNET...

The individuals on MAGNET’s mural represent just a handful of the heroes of manufacturing,...

Promise Partners, a Northeast Ohio non-profit focused on helping entrepreneurial people go from...

MAGNET is excited to launch a new program to support Northeast Ohio women in manufacturing! The...

Technological transformation is critical to Northeast Ohio's industrial livelihood, directly...

The Manufacturing Innovation, Technology and Job Center is on a t-minus countdown, as our grand...

Remember the feeling of being assigned an essay in school, when you knew what you needed to write...

Our annual Mspire pitch competition is an inspiration in innovation and creativity every year. This...

Through a partnership with GDI, the Ohio MEP is providing scholarships for a limited number of Ohio...

The Manufacturing Sector Partnership (MSP) welcomes its new leadership team this month as its...

For the past two years, the Manufacturing Leadership Team has been working together with MAGNET’s...

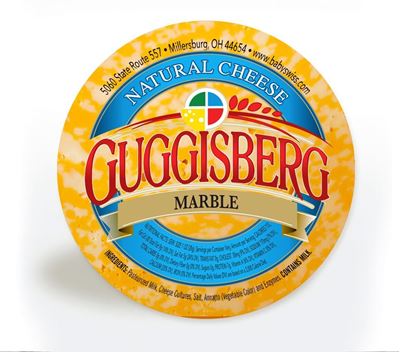

You may not always think of food as a manufactured product. But when you need to make enough of...

When the Ohio To Work initiative launched in the fall of 2020, JobsOhio was looking for ways to...

Maybe you already have and execute a marketing plan for your brand and products. Maybe you want to...

Background Formed in 2021 as a privately held subsidiary of Pittsburgh Mineral & Environmental...

Old and new, originally established and deliberately relocated here. Ohio, the northeast region...

Innovation is key to growth, specifically for Northeast Ohio manufacturers. Without thinking...

Interested in learning how to implement Industry 4.0 while mitigating the risks involved with the...

2021's success catalyzed Mspire team to take the competition to the next level. Last year’s Mspire,...

In August 2021, MAGNET began demolition and renovations on our new Manufacturing Innovation,...

Intel, which is investing more than $20B in the construction of two new chip factories in Licking...

The Urban League of Greater Cleveland and Smart Business both honored MAGNET recently for different...

Our talent development team has worked hard to become a source of thought leadership, action and...

Formerly with Target and American Greetings, Cornuke offers entrepreneurs and innovators a simple...

Manufacturers have consistently faced the same issues over the past few years: Not enough...

MAGNET recently interviewed 33 Northeast Ohio OEM and contract manufacturers to identify their pain...

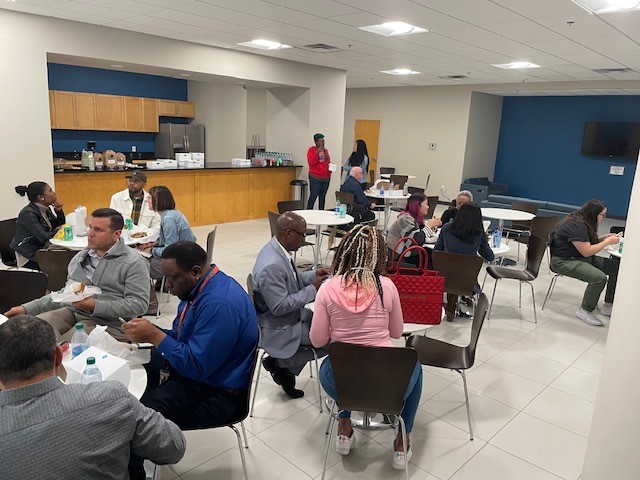

Cuyahoga County experienced some exciting manufacturing workforce development efforts this past...

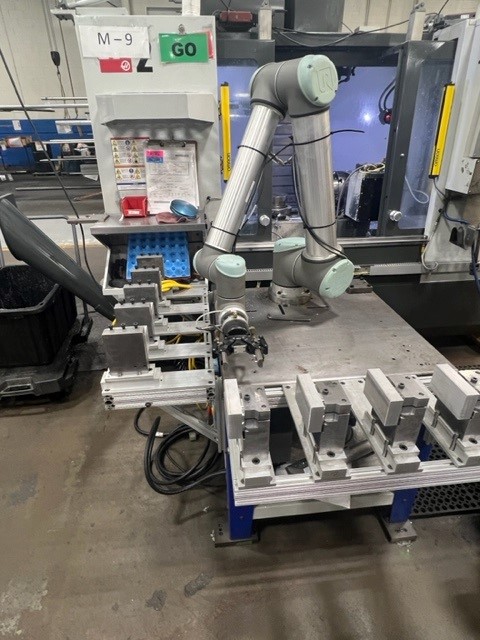

The hiring difficulties of the last few years have caused many manufacturers to reevaluate their...

“The Great Resignation” is the term that has been given to the tumultuous workforce landscape that...

Building an ACCESS to Manufacturing Careers program class requires organization, engagement and...

The Workforce Connect Manufacturing Sector Partnership formed in 2019. A group of regional...

Adam Snyder, MAGNET’s Sector Partnership Managing Director, wrote a compelling piece on...

MAGNET’s Business Development team, in conjunction with the Greater Akron Chamber and Canton...

“I wanna know what my path looks like, and I’m in a hurry to get going…” A number of years ago, a...

Successful industry sector partnership work hinges on a strong relationship with the local...

Commitment from employers to employees comes in many shapes and forms. In the current job market,...

MAGNET’s Business Development team, in conjunction with the Greater Akron Chamber and Canton...

Small and medium-sized manufacturers know that to attract talent they need to boost their entry...

As manufacturers have faced labor shortages in recent years, many have looked to attract...

Two years ago, manufacturers’ primary hiring challenge was an awareness gap, job seekers unaware of...

On October 20, 2021, 12 entrepreneurs presented their business pitches to a virtual panel of more...

CLEVELAND, OH – The U.S. Economic Development Agency selected a MAGNET-led effort as one of 60...

We’ve all seen the empty store shelves that used to be filled with hand sanitizer. It went from a...

This photo of New York nurses wearing garbage bags went viral back in March, sparking outrage and...

A metal and plastic box doesn’t sound that innovative. But this one could save lives. It’s a new,...

1,500 in two days. That’s how many Ohio manufacturers stepped up to volunteer to produce urgently...

No one has a crystal ball, but I am worried about the economic impact of COVID-19 getting worse...

On Friday February 14th, over 200 people gathered at The City Club of Cleveland for our 2020...

Unlike other states, manufacturing makes up the largest sector of the Ohio economy, and accounts...

MAGNET's Manufacturing Technology Experience has officially opened its doors, and resources, to...

As an Ohio manufacturer, you face a number of challenges and opportunities every year. To support...

How many products does your manufacturing organization produce every day? 100? 1,000? If a machine...

Manufacturers are no stranger to sales success from word-of-mouth referrals and growing existing...

For more than 30 years, MAGNET: The Manufacturing Growth and Advocacy Network has helped Northeast...

For some manufacturers, there comes a time when a new machine is needed and off-the-shelf machinery...

On Thursday, September 26, local manufacturing executives gathered at the 8th Annual Northeast Ohio...

Due to the highly connected nature of manufacturing supply chains, vulnerability to cyber breaches...

Today, small- to medium-sized manufacturers feel the pressure to produce more at a lower cost....

Many manufacturers overlook the lifespan of their machinery. While well-built machines may run for...

No matter your manufacturing goals, every company should have a set of key performance indicators...

With the rapid introduction of Industry 4.0 tools and technologies, manufacturers are under...

As the leader of a small- to medium-sized manufacturing business, you likely feel pressured to be...

Take a guess: Where does the world’s largest additive machine reside? A large city like Boston? A...

According to our 2019 State of Northeast Ohio Manufacturing Report, cybersecurity is a growing...

Are you the forthcoming owner of your family’s manufacturing business? If so, you’re not alone....

Today, many manufacturing tasks have the ability to be automated, leaving valuable employees to...