Manufacturing 101: Glossary of Machines, Processes and Parts

Manufacturing offers career endless opportunities to individuals with any skillset or level. However, the language and tools commonly used in manufacturing can be intimidating and hard to understand for those who are just learning about the industry.

Compiled below is a manufacturing glossary of processes and tools that are commonly mentioned when describing industry jobs and the responsibilities of individuals who work in the field.

Check out our index of terms, and then learn in which role you might be most interested in applying them.

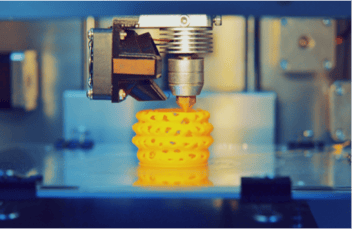

3D printing: A type of additive manufacturing in which a 3D part is constructed by a material being melted, cured and sintered. The most common types of 3D printing are FDM (Fused Deposition Modeling), where melted material is extruded, SLA (stereolithography), where liquid resin is cured using UV light, and SLS (Selective Laser Sintering), where a powder is sintered layer by layer.

Additive Manufacturing: A type of manufacturing in which the part is created by adding material as opposed to removing material. The most common example is 3D printing.

Arc Welding: A welding process that uses an electric arc to melt and join metals. This type of welding is commonly used for quick repairs of metal parts because it creates less sparks and smoke, while using higher heat.

Axis Milling: A cutting process in which the workpiece remains still while the cutting tool moves along the axes to mill the part. These machines can make everyday metal furniture to jet engine rotors for the aerospace industry.

Bellows: These pumps circulate air and are used in manufacturing to keep fires burning and workspaces and machinery clear of debris. Bellows can be found on the manufacturing floor blowing debris off machinery and speeding up combustion on an iron worker’s forge.

Brazing: Brazing is joining two or more metal pieces together with a metal that has a lower melting point, so you can attach the workpieces without melting them. This method is often used when the product’s base metals are too difficult to melt precisely.

CAD: Stands for Computer-Aided-Design and refers to the use of a wide range of computer-based tools. that assist engineers, architects and other design professionals in their projects.

CNC: CNC = Computer Numerical Control. This term is often used to refer to a machine that is controlled by a computer instead of manually. CNC machines are useful when producing large quantities of a product to ensure its exact specifications.

Die: A specialized machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Die machines are generally customized for each product that they are used to produce.

EDM: Electrical Discharge Machinery (EDM) is a metal fabrication process where metal is shaped by electrical charges. This method of metal forming is most commonly used when working with heavy, dense metals and is extremely precise.

Flame-Cutting: A method of cutting in which the appropriate part if the material to be cut is risen to ignition temperature, using an oxy-fuel gas flame. This process is most commonly used to separate or shape steel components.

Forge: A type of hearth used for heating metals. A forge is used to heat a piece of metal to a temperature at which it becomes easier to shape and the workpiece stops hardening.

Forging: a manufacturing process that shapes metal using localized compressive forces. The blows are usually delivered with a hammer or die.

Lathe: A machining tool used primarily for shaping metal or wood. The lathe rotates the workpiece around a stationary cutting tool until the piece is the proper shape. Lathes are mainly used to remove unwanted parts of the workpiece, leaving behind a specifically and cleanly shaped product.

Machining: A process in which a material is cut to a desired final shape and size by a controlled removal process. There are several machines that carry out this process, and it can be done with almost any type of material including metals, plastics, and wood.

OEM: Stands for Original Equipment Manufacturer and refers to a company who produces components in the product of another company, which then sells the finished product to consumers. Most Northeast Ohio manufacturers are OEMs.

Shearing: Cutting any material to the required specifications. Shearing is used in almost every department of manufacturing, and several machines are used specifically for shearing.

Subtractive Manufacturing: The most common type of manufacturing in which material is removed from a part to make it (examples include drilling, milling, cutting and sanding)

Stamping: Also referred to as pressing, stamping involves placing flat sheets of material into a stamping press where a tool and die surface form and cut the material into the desired shape. Stamping is used to create countless products but is most commonly used to shape metal. Punching, blanking, bending, coining, embossing and flagging are all stamping techniques used to shape materials.

Soldering: A way to join two or more metal pieces using a type of metal that melts at low temperatures. Different from brazing, soldering uses lower flame temperatures to join pieces of metal together. It is most commonly seen in electronics and plumbing.

Threading: The process of creating a screw thread, either by cutting away at the material to create grooves or adding threads onto the material via 3-D printing.

Ready to join one of our manufacturing career programs? Chat with us here.