Ohio Innovation on Display at Diamond Wipes Lighthouse Tour

MAGNET’s first Lighthouse Tour of 2025 took us to Bucyrus, Ohio, for a behind-the-scenes look at a...

Manufacturing

growth partners.

We’re manufacturers who work closely with your team to create measurable results. High-touch, high-impact consulting is part of our DNA.

We roll up our sleeves

Our diverse team of manufacturing experts use their skills and expertise to make good things great, to make great things excellent, and aim to make excellence standard in Ohio.

Building Northeast Ohio’s Future

Connecting with and changing the lives of Northeast Ohioans through smart manufacturing

Blueprint for Manufacturing in Northeast Ohio

Northeast Ohio has everything it needs to lead the world in smart manufacturing. We just have to do what we do best: Make It Better. Together.

MAGNET’s first Lighthouse Tour of 2025 took us to Bucyrus, Ohio, for a behind-the-scenes look at a...

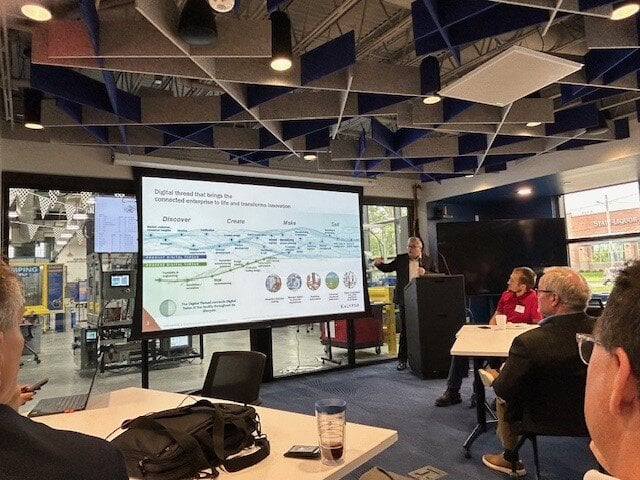

Local manufacturers gathered at Rudolph Libbe Group's (RLG) Northeast Ohio office for a dynamic...

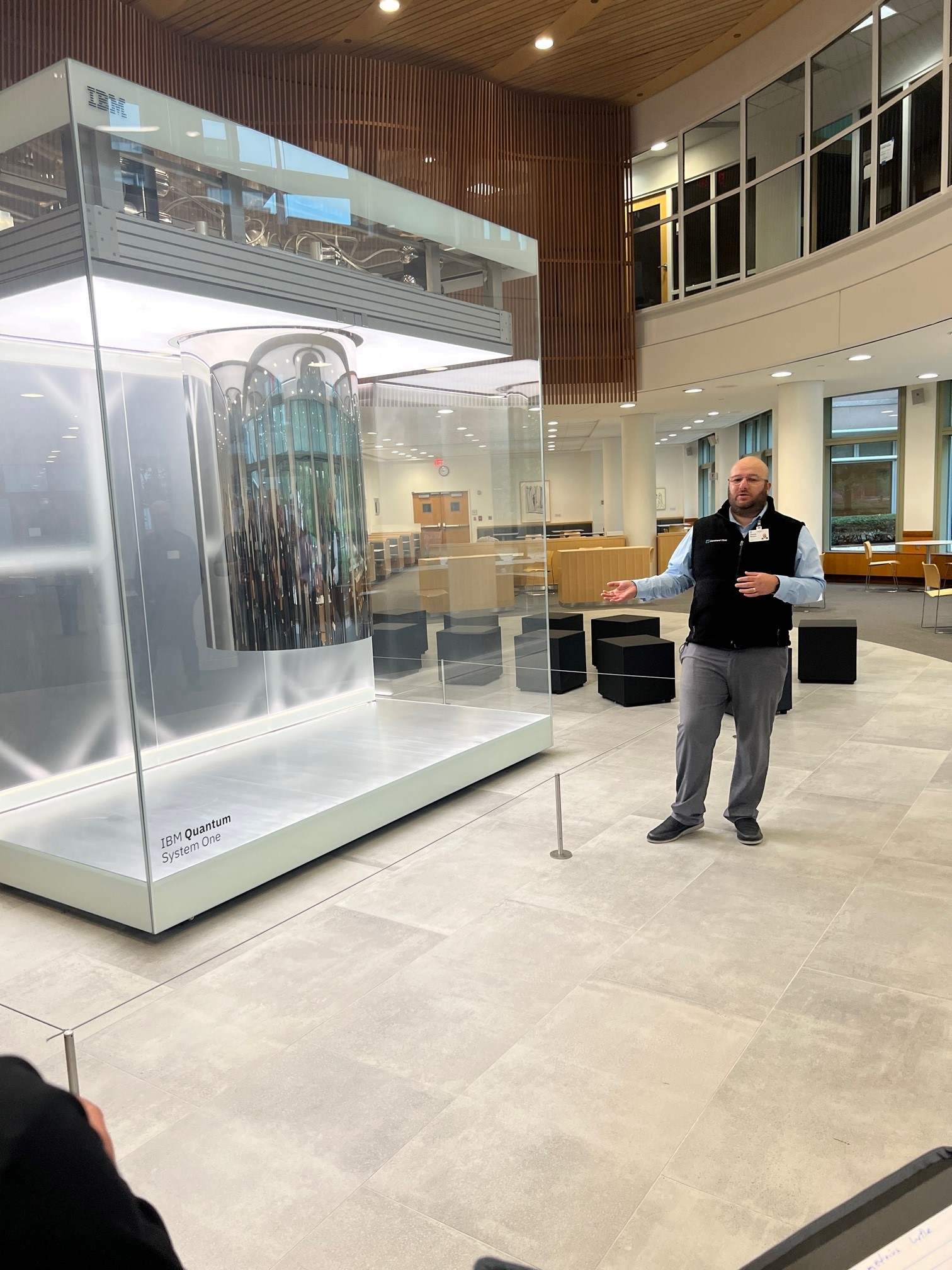

On November 21, 2024, industry leaders gathered at ISSQUARED Technology Center in Chardon, OH, for...

Forging the Future: Celebrating MAGNET's 40th Anniversary Entrepreneurs and small business leaders...

In 1984, MAGNET embarked on a mission to empower Northeast Ohio’s manufacturing industry. 40 years...

MAGNET hosted innovators of all kinds, from CEOs to entrepreneurs, for an engaging and...

MAGNET proudly announces the winners of its 9th annual Mspire pitch competition, Northeast Ohio’s...

MAGNET held its annual Mspire competition today! Our judges heard from 11 entrepreneurs who are...

MAGNET's recent Lighthouse Tour at Welser Profile was an enlightening experience, showcasing not...

Location, location, location. The North Central Ohio Industrial Museum location, nestled in the...

MAGNET Strategy, Marketing and Sales Director and certified Scaling Up Coach Dave Sluka recently...

Thank you for your interest in Mspire, MAGNET's annual Pitch Competition, the premier event in...

Local manufacturers and economic development professionals gathered at MAGNET this week to hear...

MAGNET’s 8th annual Mspire pitch competition brought together the best and brightest in the...

Mid’s Homestyle Pasta Sauce is a tradition 65 years in the making, when Mideo Octavio first bottled...

EDGE’s Innovation Management Program, InnoQuest, brings together innovation leaders from 20+...

Our annual Mspire pitch competition is an inspiration in innovation and creativity every year. This...

Through a partnership with GDI, the Ohio MEP is providing scholarships for a limited number of Ohio...

Old and new, originally established and deliberately relocated here. Ohio, the northeast region...

Innovation is key to growth, specifically for Northeast Ohio manufacturers. Without thinking...

2021's success catalyzed Mspire team to take the competition to the next level. Last year’s Mspire,...

Formerly with Target and American Greetings, Cornuke offers entrepreneurs and innovators a simple...

MAGNET recently interviewed 33 Northeast Ohio OEM and contract manufacturers to identify their pain...

MAGNET’s Business Development team, in conjunction with the Greater Akron Chamber and Canton...

On October 20, 2021, 12 entrepreneurs presented their business pitches to a virtual panel of more...

We’ve all seen the empty store shelves that used to be filled with hand sanitizer. It went from a...

This photo of New York nurses wearing garbage bags went viral back in March, sparking outrage and...

A metal and plastic box doesn’t sound that innovative. But this one could save lives. It’s a new,...

1,500 in two days. That’s how many Ohio manufacturers stepped up to volunteer to produce urgently...

Did you know 70% of all new product launches fail? While manufacturers may feel a sense of urgency...

You have a company that’s experienced some success, but you need more. You want to excel in...

Marketing is hard. Whether you’re an established company or a nimble startup, it’s easy to get...

Product design requires many phases. It’s the process of identifying market potential by clearly...

Maybe you’ve heard: new product launches are often unsuccessful. Some studies state failure rates...

This post is part of a series on creating a manufacturing business strategic plan, which reflects...

This post is part of a series on creating a manufacturing business plan, which reflects your goals...

We can all agree that for a business to be successful, it needs customers. But to attract, retain,...

Product innovation is the motor of a thriving manufacturing business. Without it, businesses and...

Northeast Ohio manufacturers, ranging from startups to well-established companies, are...

For Continuous Improvement to be effective and sustainable, it requires a systems approach...

How a minimum viable product will launch your product-based startup. There’s plenty of conversation...