Driving Growth and Efficiency: Key Takeaways from the Ashtabula County Manufacturers’ Operational and Energy Efficiency Forum

On May 7, manufacturers from across Northeast Ohio gathered at The Lodge at Geneva-on-the-Lake for a dynamic morning of insight and collaboration at the Ashtabula County Manufacturers’ Operational and Energy Efficiency Forum. Hosted by MAGNET in partnership with Growth Partnership for Ashtabula County, Lake to River, and YWRC, the event brought together industry leaders, community stakeholders, and government representatives to explore strategies for strengthening local manufacturing.

On May 7, manufacturers from across Northeast Ohio gathered at The Lodge at Geneva-on-the-Lake for a dynamic morning of insight and collaboration at the Ashtabula County Manufacturers’ Operational and Energy Efficiency Forum. Hosted by MAGNET in partnership with Growth Partnership for Ashtabula County, Lake to River, and YWRC, the event brought together industry leaders, community stakeholders, and government representatives to explore strategies for strengthening local manufacturing.

Attendees heard remarks from representatives of U.S. Congressman David Joyce and Senator Moreno's offices (Ariann Smith and Beth Bingham respectively), underscoring the importance of manufacturing to the region’s economic vitality. Greg Myers and Alexa Sweeney-Blackann echoed this sentiment, emphasizing collaboration as the key to sustainable growth.

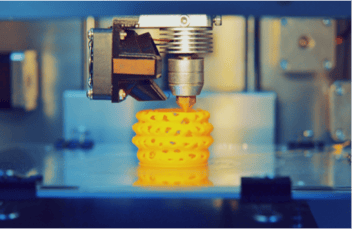

When introducing the forum, MAGNET COO of Consulting, Mike O’Donnell reinforced that relationships—with employees, community leaders, and government officials—are at the heart of successful manufacturing growth. He reminded attendees that small to mid-size manufacturers create 75% of new jobs, and now is the time to embrace the "factory of the future" mindset. Drawing inspiration from Mark Lamoncha’s book The Industrial Athlete, he described how real-time incentives and gamification strategies can help companies drive engagement and productivity.

During the panel discussion led by Client Engagement Director Darlyn McDermott, real-world success stories were shared from manufacturers who are actively transforming their businesses through operational improvements and partnerships with MAGNET.

-

Doug Rende of Shapes Unlimited shared how value stream mapping and layout marketing helped his company increase inventory turns from just half a turn to three turns per year, boosting EBITA by an impressive 70%. His “secret sauce”? Building an inclusive culture that includes individuals who come to them through the Flying High, Inc. program, and creating growth opportunities for current employees.

-

Jeremy Kerola of UniServ, LLC detailed his company’s focus on employee development and process improvements as it grows from 118 to 135 employees. With a focus on change management and documented processes—starting from the ground up—Jeremy emphasized the importance of building energy into his culture.

-

Bridget Redecker of Distinctive Details discussed her plans to more than triple her workforce, growing from 15 to 50 employees. Working with MAGNET, her team is applying lean principles, eliminating waste through 5S strategies, and cultivating a culture that drives its own ROI.

-

Keith Wyatt of Grand River Rubber highlighted the critical need for equipment upgrades to improve production rates. Partnering with MAGNET, his company is building new machines to enhance efficiency and unlock greater profitability, with automation and equipment upgrades as their competitive advantage.

-

Damon Walsh of ITEN Defense showcased how a strong company culture can be a powerful growth catalyst. With no PTO restrictions and competitive salaries as part of their unique “secret sauce,” ITEN is rapidly expanding, including plans for a major military contract supported by its innovative transparent armor product line.

Closing out the event, business leaders were challenged to avoid stagnation and instead focus on the four pillars of growth: People, Strategy, Execution, and Cash—a proven framework from the methodologies of Scaling Up and Traction. With MAGNET’s support, manufacturers are well-equipped to grow stronger businesses today and build resilient, future-ready factories that will serve generations to come.